Explain the Difference Between Ductility and Malleability

They can be beaten into sheets and wires. In common language ductility refers to the ability to be deformed without losing toughness.

Difference Between Ductility And Malleability The Engineering Knowledge

Malleability and ductility are both manifestations of a metals or alloys ability to be plastically deformed without breaking.

. Ductility is the ability to be drawn into wires. Explain the term fatigue. They do not allow heat and electricity to pass through them.

Using what you have learned about atomic bonding in different materials explain the differences in electrical conductivity and mechanical properties malleability ductility between metals and ionic solids. Also explain the term fatigue strength and fatigue. Malleability and ductility are related.

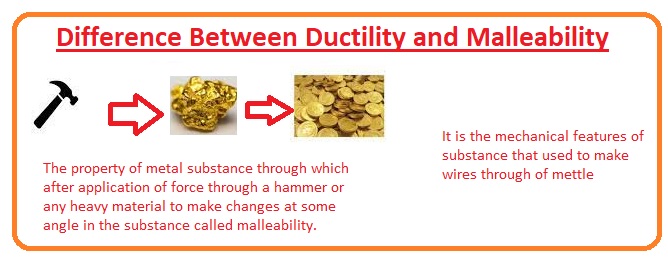

Malleability is the ability to be flattened with a hammer or roller. Ductility is the ability of a material to withstand tensile force when it is applied upon it as it undergoes plastic deformation. Ductility and malleability are properties related to deformation of metals.

A malleable material is one in which a thin sheet can be easily formed by hammering or rolling. Malleability is the property of a material that changes its form when compressed eg. They are similar in that they both refer to a metals ability to withstand stress without rupturing but opposite in terms of the type of stress being applied.

Toughness is the ability for the process of fracture to absorb energy. Most metals have both malleability and ductility. This is the main difference between ductility and malleability.

Explain The Meaning Of Malleable And Ductile. Sketch this defect below. They cannot form sheets or wires.

8 rows The significant difference between ductility and malleability is that ductility is the. If a material is malleable then it can be converted into thin sheets by hammering or rolling. Ductility and malleability are two properties that are of great importance in selecting materials.

Pounded into thin sheets. Malleability is the ability of a material to deform under stess compressive stress. Steel can be pounded into thin sheets.

Malleable means the ability to be hammered or pressed into shape without breaking or cracking. Ductility is the ability of a metal to undergo tensile stress. Long wires are useful to connect a television to an outlet that is on the other side of the room.

Ductility of a material is the ability to stretch under stress tensile stress. Ductility and malleability are two properties of metals that describe specific tendencies in certain metals. Ductility is the property of being drawn into wire.

They cannot form sheets or wires. 4 rows Malleability is defined as the ability of solid material to plastically deform to a larger extent. Ductility describes the property of the ability to stretch a metal.

Malleability refers to the property of a material to get deformed under. Brittleness is the opposite of ductility as it refers to the ability of materials to break into pieces upon application of tensile force without any elongation or plastic deformation. Ductility is the ability to be made longer and thinner by pulling.

Malleability describes the property of a metals ability to be deformed under compression. Malleability is the ability to be pounded into thin sheets. Ductility has to do with tensile stress whereas malleability deals with.

THE DIFFERENCE BETWEEN DUCTILITY AND MALLEABILITY. Chemical properties Nature of oxides. Copper can be drawn into long wires.

On which factors does these properties mainly. They conduct heat and electricity. Explain the difference between hardness and brittleness strength and stiffness elasticity and creep malleability and ductility.

That is pliable but not brittle. Plasticity It is a property by virtue of which metal can be deformed in to desired shape. The terms ductility and malleability are often used interchangeably.

It is a permanent strain that accompanied fracture in a tension test. It is a desirable property in machine components that are subjected to unanticipated. They can be beaten into sheets and wires.

What types of defects allow metals to be malleable and ductile. Some of the more important properties peculiar to solids are malleability and ductility. The key difference between ductility and malleability is that ductility of solid material is the ability to undergo tensile stress without fracture or damage whereas the malleability of a material is the ability to undergo compressive stress without fracture or damage.

Sonority Metals are sonorous they produce a ringing sound on beating. What do you understand from the term Mechanical Properties of Materials. Ductility It is property by virtue of which metal can undergo considerable plastic deformation before fracture Elasticity It is property by virtue of which metals regains its original size and shape after removal of external load.

Conduction They conduct heat and electricity. Metals are sonorous they produce a ringing sound on beating. In other words the material has the ability to deform under compressive stress.

Non-metals do not allow heat and electricity to pass through them. The sheets are useful for building car bodies. Malleability denotes the ability to undergo compressive stress.

5 points A stress-strain plot. Ductility describes the property of the ability to stretch a metal without being damaged. Ductility is the property of a material to stretch without suffering any damage.

Difference Between Ductility And Malleability Compare The Difference Between Similar Terms

Difference Between Ductility And Malleability

Difference Between Ductility And Malleability Pediaa Com

Differentiate Between The Following With Suitable Examples I Mineral And Ore Ii Corrosion And Rancidity Iii Malleability And Ductility

Belum ada Komentar untuk "Explain the Difference Between Ductility and Malleability"

Posting Komentar